Alex Rawitz, Business Development Manager, Servato

The accelerating growth of Internet of Things (IoT) devices and applications require continuous investment in telecommunications networks to provide the connectivity for millions of new devices. As more devices connect to the Internet, service outages become more impactful to the people and businesses that rely on IoT applications. Safeguarding telecom networks from power outages is the Valve Regulated Lead Acid (VRLA) battery. Stationary VRLAs are ubiquitously used at broadband, wireless and cable sites, and millions are in service across the country. Unfortunately, almost all of these batteries, and thus the sites that depend on them, are vulnerable to a reliability-damaging standard: float charging. While float charging will maintain batteries at full charge, it can have a damaging impact on the service life of the battery, which introduces risk and increases maintenance costs. There is a better way to charge batteries, Adaptive Charging, that mitigates the degrading effects of float charge, extending battery life and reducing maintenance costs.

Inefficiencies of Continuous Float Charging

Before describing the inefficiencies of continuous float charge and VRLA maintenance inefficiencies, it’s important to understand why VRLAs are, and will remain, the battery of choice for telecom outside plant deployments. Though the trade off has reduced the service life of VRLAs compared to their flooded counterparts, the elimination of watering has been a major improvement for battery maintenance. Most importantly, VRLAs are cheap and generally reliable. Lithium Ion, Ni-Cd, and other chemistries simply cannot top the convenience of VRLAs. The telecom industry is not looking to change the batteries it orders or the power engineering of its sites anytime soon.

But every technological step involves some give and take and it seems with batteries this is a particularly dependable axiom. VRLAs are sealed and thus the heat generated by an exothermic gas recombination mechanism is trapped inside the battery and can only be removed by transmission through the container walls. Continuous float charging generates continuous heat within the batteries. The heat levels are exacerbated by closely packed batteries in telecom installations and the likelihood of high temperatures found in metal cabinets that sit in the sun all day.

Higher internal battery temperatures accelerate failure. A cabinet like the one on the right could routinely reach temperatures in excess of 60°C during the summer, and a “10-year” battery with a true expected life of four to six years may only deliver 2 years of service.

All this heat from oxygen recombination, hot summer temperatures and poor air circulation in the cabinets, drives up the rate of battery degradation, and thus the risk of network failure when the batteries are not sufficient to provide backup power. Increased battery temperature from gas recombination accelerates:

- Grid Corrosion

- Dehydration

- Dry-Out

In addition, active material degradation and capacity loss take place as a result of:

- Plate Softening

- Loss of Cohesion

While continuous float charging is a sufficient way to maintain fully charged batteries, the relentless heat generation introduces risk to the system by accelerating battery failure. This means maintenance trips are required much more often (when there is capacity for the workforce to absorb the extra trips), driving up cost. Often there are not enough workers to test and replace the batteries and the failed batteries remain in the field for months or even years. Today, most telecommunications companies rely on cyclical maintenance that may involve checks as frequently as every few months, but they can happen as infrequently as once a year.

These long periods of time without a site check mean that battery health readings provide limited insight into true battery health. If a plant manager or network technician does not have enough battery data, he or she cannot make predictions about battery life and will find it impossible to take proactive steps to protect reliability. Further, equipment failures of other kinds such as fans, heat exchangers or rectifiers can end up damaging batteries in other ways not related to a continuous float charge. If the charging regimen could be changed, many of these inefficiencies could be reduced or eliminated and reliability could be improved.

Intermittent or Periodic Charging

“Intermittent” or “periodic” charging schemes have been tested as ways to improve continuous float charging. In “intermittent” or “periodic” charging, the ratio of float time to open circuit time is fixed; no matter what the battery or environmental conditions are. The cycle of charge and rest proceeds at fixed intervals.

This charging methodology reduces time on float and thus overcharging, but still has shortcomings. First, the correct ratio of float to open circuit time is a moving target dependent on temperature and battery condition and a fixed cycle cannot compensate. An incorrect ratio can result in overcharging or undercharging.

A float to open circuit ratio that might be adequate at 40°C will not be satisfactory at higher or lower temperatures because of different rates of corrosion and dry out. The rate of self-discharge is temperature dependent and the amount of charge required to maintain 100 percent state of charge at 40°C will be considerably greater than at 25°C. These magnitudes of temperature fluctuations are common, especially in outdoor cabinets, and with a fixed charge-to-rest ratio it is impossible to continually adjust float voltages and currents to maintain an optimum charge.

A further weakness is that a fixed ratio may not be capable of compensating for power outages. In cases where numerous short power outages occur, the charge period must also be long enough to restore the battery to full charge. A fixed ratio does not meaningfully improve upon standard float charging. To compensate for varying rates of self-discharge at different temperatures and ensure maximum battery charge for use, the ratio of open circuit to float needs to adapt.

Adaptive Charging

Adaptive Charging is a methodology that uses battery data to administer battery-charging needs on an ever-changing basis. Batteries are only charged exactly as much as is necessary and otherwise remain in an isolated state; they are “virtually disconnected” from the bus, but are capable of providing instantaneous backup power. Using a unique hardware appliance capable of automated testing and charge control, data is automatically collected on pertinent battery parameters many times per day to ensure that batteries end each day fully charged. The practice also allows the identification of thermal runaway and other potentially negative issues.

Adaptive charging uses a dv/dt charge termination to ensure that charging stops immediately when the battery is fully charged, thereby preventing continuous overcharge and overheating. It adapts to the depth of discharge of the preceding discharge and compensates for the effect of temperature. That is, dv/dt = 0 indicates that the battery is charged whether it is at 25°C or 40°C, and whether it has experienced a recent discharge or simply been isolated at rest. This also eliminates the need for temperature compensation of the rectifier.

Certain measurements collected by the appliance, such as open circuit voltage (OCV), internal resistance and voltage under load give a good indication of whether a battery needs to be charged or replaced.

Adaptive Charging and the testing associated with it produces a wealth of battery data and is conducive to advanced analysis of battery signatures to detect harmful trends. The link between maintenance and performance is strong, and a tool that provides monitoring and management capabilities is a major asset to battery managers in telecommunications and other industries.

Principles of Adaptive Charging

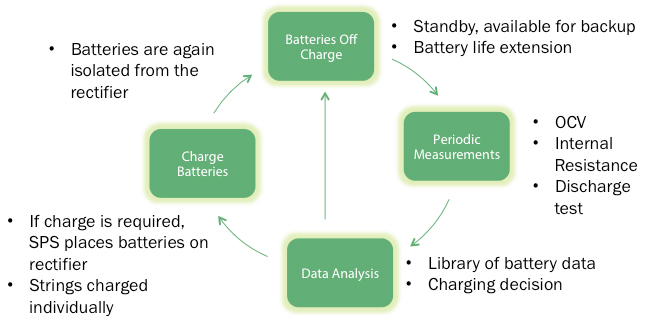

The basic principle of Adaptive Charging is to minimize the amount of time batteries spend on float while maintaining full charge for backup applications. This is executed by cycling the batteries through an automated testing regimen that intelligently decides after every test whether the batteries need to be charged.

Batteries are maintained in a standby (off charge) mode by isolating them from the rectifier bus via Servato’s proprietary technology. The VRLAs are charged about 20 percernt of the time and at rest about 80 percent and are still kept at full capacity. Limiting the oxygen recombination reaction that causes degradation significantly increases battery life. In this standby mode, batteries are still available for instantaneous discharge in case of a power outage.

While the batteries are at rest they are monitored at periodic intervals multiple times per day. Servato uses OCV and Temperature to indicate state of charge. State of Health is determined by evaluating several parameters including DC Resistance, charge efficiency, and self-discharge rates, among others. All battery data is parsed for any trends that may indicate existing or developing battery issues.

The measurements are collected and analyzed automatically and compared to a library of battery data accumulated through more than 5 million battery-operating hours. If stable, the batteries are allowed to remain in the standby mode for a period of time when they will be tested again. If the data show changes greater than embedded set points a charge is initiated.

If and only if charging is necessary, the batteries are put on the rectifier bus until they are fully charged to the dv/dt charge termination point. This replaces energy lost through self-discharge and any short-term discharges that may have occurred. As soon as the full charge criteria are satisfied the batteries are again isolated from the rectifier. If the batteries have been discharged for more than a preset time during the standby period they are immediately connected to the rectifier for charging to eliminate any possibility of standing in a partially discharged condition.

In a multistring application, the strings are charged sequentially to assure string-to-string equalization. Each string is brought to full charge independent of the other strings in the system. This reduces the adverse affects caused by random inter-string variation. Following any charge event the battery strings are given a State of Health test. A short discharge is applied to the batteries. Voltage and time characteristics are recorded and used to calculate the internal resistance.

Adaptive charging assures that the batteries are charged whenever the data trends indicate that a charge is necessary and not anymore, and it automatically compensates for normal temperature-dependent phenomena such as self-discharge. Compared to continuous float charging or intermittent charging, Adaptive Charging offers a way to improve battery service life and reliability.

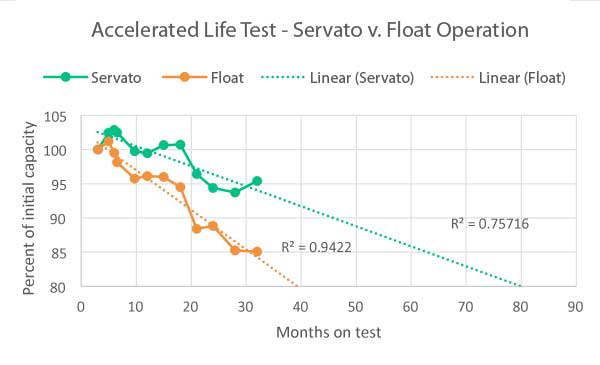

This battery life extension is not just a theory. Laboratory and field data confirms the ability of Adaptive Charging to extend battery life. An independent test laboratory was used to compare the capacities of VRLA batteries over time when they were on continuous float and when subjected to an Adaptive Charging regimen. Tests were carried out according to the Time Warner Accelerated life test protocol. Four strings of batteries were tested, battery capacities were measured at approximately three-month intervals and averaged and charted as shown in Figure 4.

Adaptive Charging Extends Battery Life and Delivers other Benefits

Continuous charging as a method of maintaining standby batteries at a full state of charge has been standard for many years, but has serious negative consequences that can add significant cost to battery management budgets. Continuous float charging accelerates battery failure due to increased temperature, grid corrosion, plate degradation and dry-out.

For companies that depend on backup batteries, this inevitably leads to higher capital and maintenance costs. Battery life can be increased by removing these harmful failure mechanisms and by charging only when necessary and only for as long as necessary. Adaptive charging combines an automated battery management process and a remote monitoring solution to maximize visibility into backup batteries.

- Adaptive Charge Management delivers meaningful and measurable benefits in four strategically important areas:

- Battery Life Extension: Adaptive Charging improves battery life through the mechanisms described above

- Site Insight: Adaptive Charging needs great battery data, which makes it easier to detect battery and equipment issues remotely

- Optimized Maintenance: Better insight means better maintenance, reducing costs and improving reliability and

- Other Reduced Costs: Battery life extension and optimized maintenance are key pieces, but the business case has many other cost savings associated with Adaptive Charging.

For more information, contact Servato Corp.